Very much like transport lines, the starting points and history of force transmission belts are lost in the fogs of time. While we accept that the Babylonians and Assyrians involved chains and cups for water-drawing machines, the earliest notice of a mechanical belt drive with a pulley machine is in a Chinese text from 15 BCE. This portrays the way things were set up to breeze silk filaments onto bobbins for weavers’ vans. Around 1,000 years after the fact, when the main detailed automated turning wheel was recorded, again in China, it depended on a belt drive. I view this as entrancing – because the material business is yet home to various applications for power correas de transmisión today.

Power transmission belts run as expected and unobtrusively, assisting with safeguarding hardware from over-burden and sticking and protecting engines and orientation against load changes. They need insignificant support and are exceptionally effective (up to 98%). As you’d expect, the materials utilized for power correas de transmisión have changed throughout the long term. While previously, level belts were normally made of cowhide, during the nineteenth century they additionally utilized ropes made of cotton, hemp, flax, or even wire.

Be that as it may, power transmission with calfskin belts stayed a well-known answer for quite a long time. Indeed, even toward the start of the twentieth century, calfskin belts were the cutting-edge answer for effective power transmission. You can see this in pictures that show, for instance, a studio with a vitally driving shaft on the roof, with processing machines, machines, boring machines, and other gear running off it, all determined by calfskin belts.

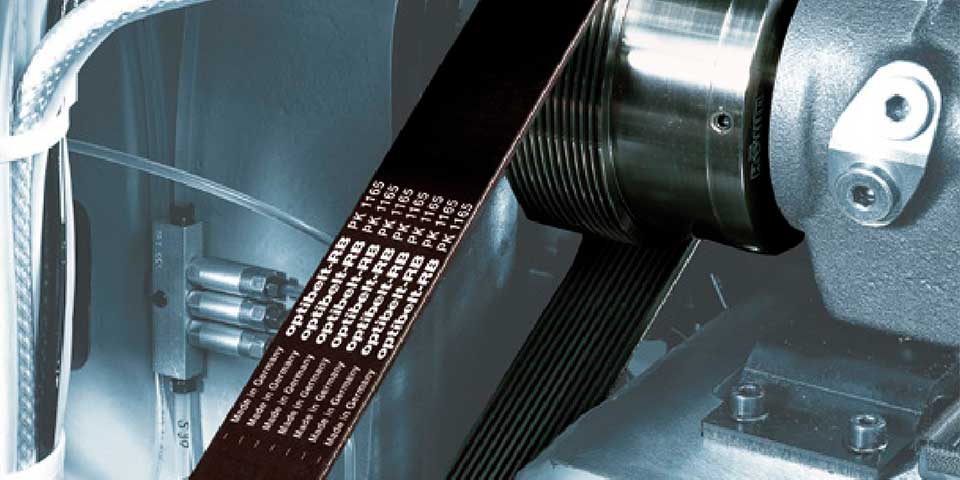

Power transmission belts have tracked down numerous new and significant purposes today. And keeping in mind that they keep on assuming a main part in present-day machine plan, they are less apparent than previously, as generally speaking they are safeguarded by the machine outline and play out their undertaking ‘undercover.’ The accompanying models show the abilities of this remarkable machine component in various businesses:

Power transmission belts for punching machines, presses, and so on, have a difficult situation since they need to send extremely high loads. They likewise need to assimilate shocks, for instance, over-burdens, to safeguard other machine components like engines and direction.

In appropriation and package arranging focuses, power transmission belts drive the live rollers. Belt execution is definitive here for exact arranging with the most elevated machine throughput and the least expenses and energy utilization. These belts make a significant commitment to the quick and opportune conveyance of your web-based orders.